Introduction

When it comes to industrial filtration, choosing the right filter can make all the difference. Two of the most widely used options are Duplex Filters and Twill Wire Mesh Filters. Both serve critical roles in industries, but their applications differ. This blog will help you understand the key differences and decide which one is best for your industry.

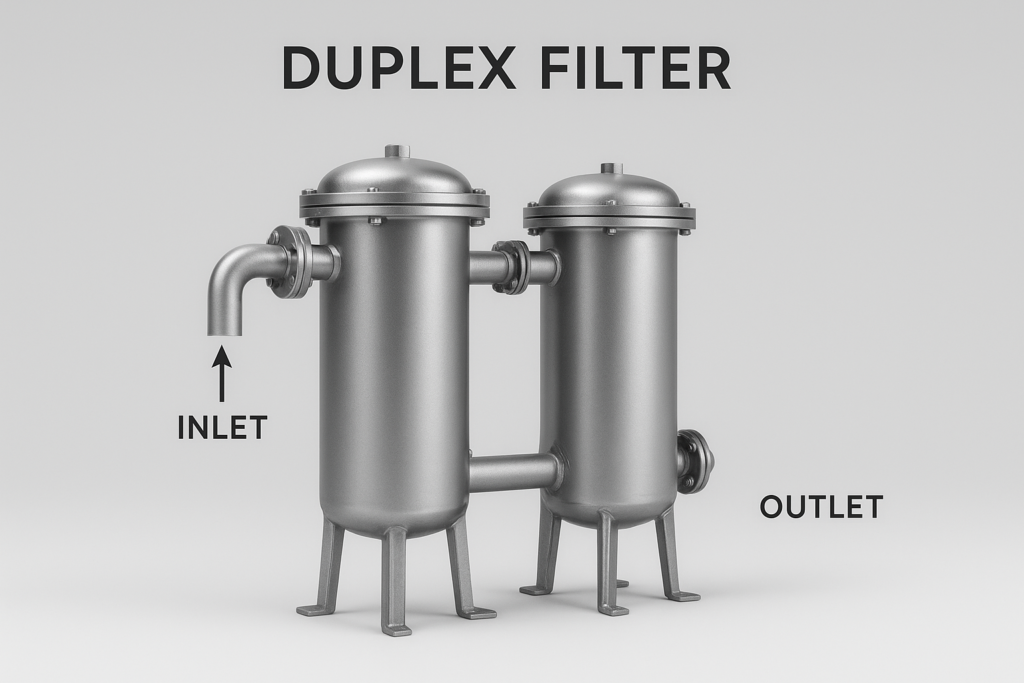

What is a Duplex Filter?

A Duplex Filter consists of two filtration chambers connected by valves. One chamber works while the other can be cleaned or maintained — ensuring continuous operation.

Key Benefits:

- No downtime during maintenance

- Handles large flow rates

- Ideal for industries requiring uninterrupted processes

Industries Using Duplex Filters:

- Marine & Shipping

- Oil & Gas

- Petrochemicals

What is a Twill Wire Mesh Filter?

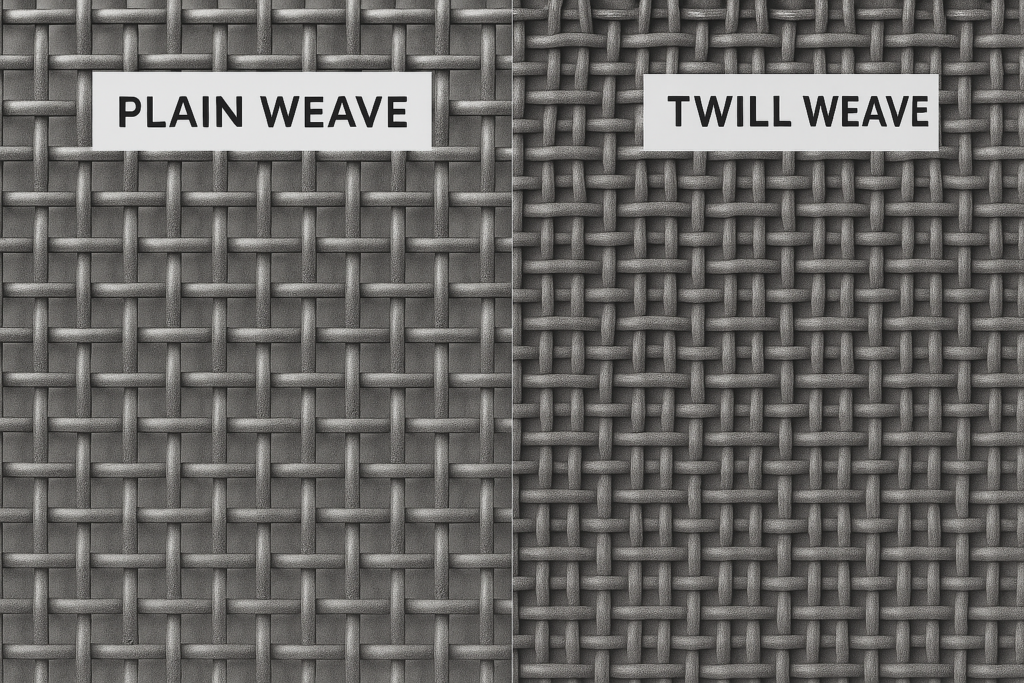

A Twill Weave Mesh is created by weaving each weft wire alternately over and under two warp wires. This makes it stronger than plain weave and ideal for fine filtration.

Key Benefits:

- Higher strength than plain weave

- Excellent for filtering fine particles

- Withstands higher pressure

Industries Using Twill Mesh Filters:

- Pharmaceuticals

- Aerospace

- Chemical Processing

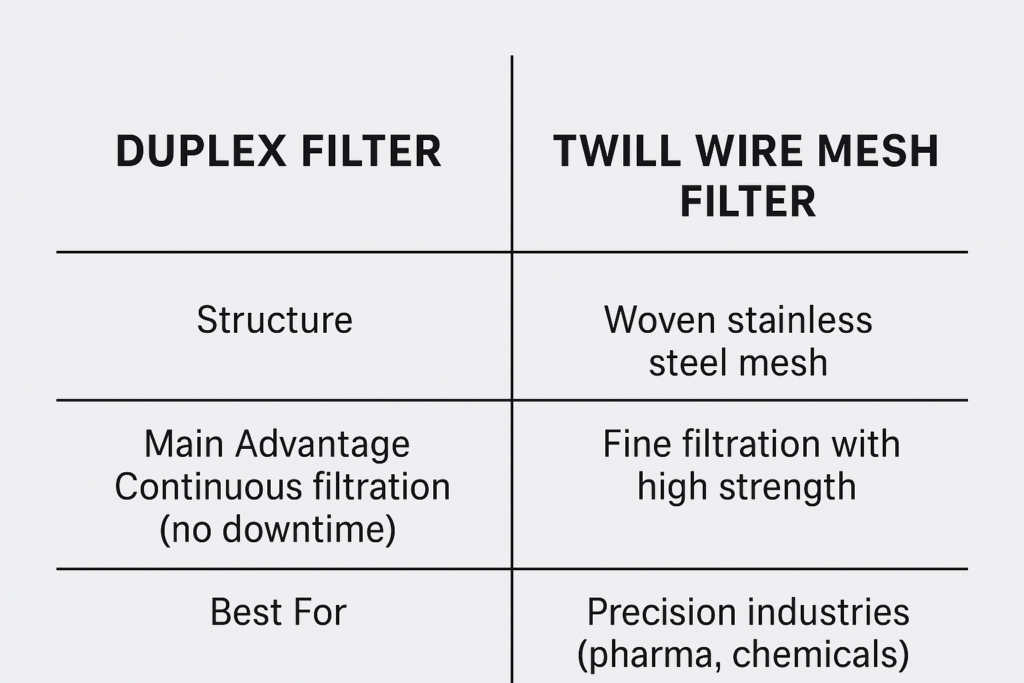

Duplex vs. Twill Wire Mesh – Quick Comparison

| Feature | Duplex Filter | Twill Wire Mesh Filter |

| Structure | Two filter chambers | Woven stainless steel mesh |

| Main Advantage | Continuous filtration (no downtime) | Fine filtration with high strength |

| Best For | Large-scale fluid systems | Precision industries (pharma, chemicals) |

Conclusion

Both Duplex Filters and Twill Wire Mesh Filters are excellent choices, but their applications differ. Duplex filters excel in heavy-duty, continuous processes, while twill wire mesh is best for precision industries.

👉 Need help deciding? Contact Alankrit Wire Craft for expert guidance and customized solutions.