Introduction

When it comes to industrial filtration, stainless steel circles play a vital role in customized filtration equipment. These precision-cut mesh pieces are designed to fit specific machines and applications. In this blog, we’ll cover their top benefits and industries that rely on them.

Top 5 Benefits of Stainless Steel Circles

- Custom Fit for Equipment

- Tailored to exact sizes for unique machinery.

- Durability & Strength

- Resistant to wear, heat, and corrosion.

- Efficient Filtration

- Provides uniform separation for liquids and gases.

- Cost-Effective

- Reusable and long-lasting compared to synthetic filters.

- Versatile Applications

- Used across food, petrochemical, and automotive industries.

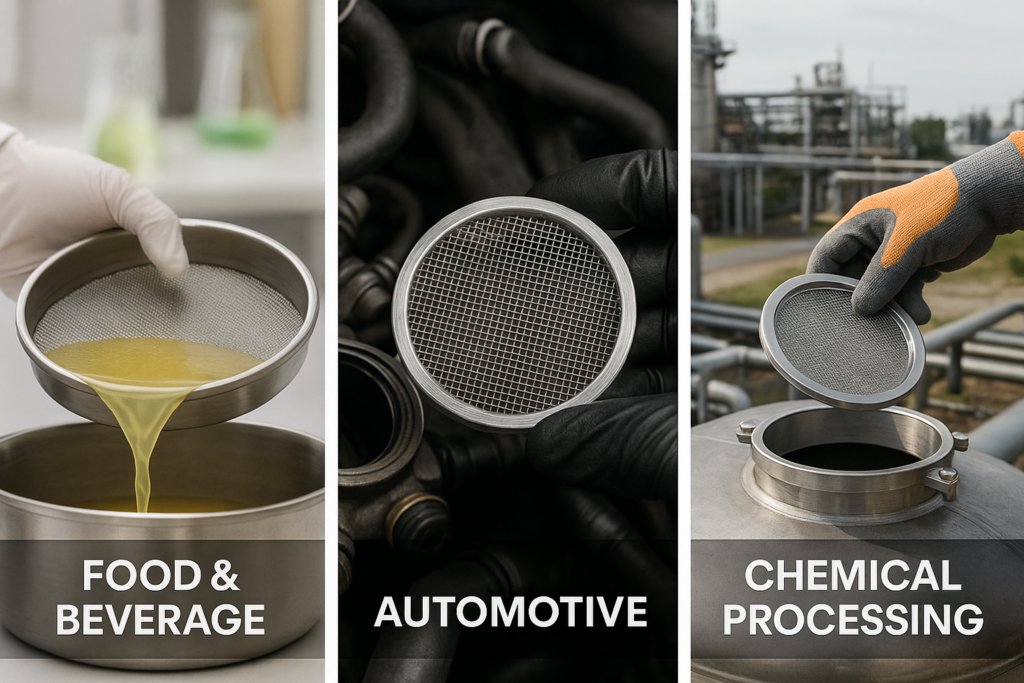

Industries Using Stainless Steel Circles

- Food & Beverages – Filtering liquids and powders

- Automotive – Oil and fuel systems

- Chemical Processing – High-pressure filtration systems

Conclusion

Stainless steel circles may look simple, but they play a critical role in industrial filtration. Their strength, precision, and versatility make them indispensable across industries.

👉 Get in touch with Alankrit Wire Craft for customized stainless steel circles designed to meet your specific needs.