Introduction

Every industry that relies on separation, screening, sieving, or filtration depends heavily on one core factor: the mesh size and aperture of the wire mesh. Whether it’s flour in a food plant, chemical filtration in a refinery, or aggregate screening at a construction site—choosing the right mesh is essential to maintain product quality, efficiency, and safety.

Yet, mesh size and aperture are the most misunderstood parameters by buyers.

In this detailed guide, we break down:

- What mesh size really means

- How aperture changes filtration performance

- How wire diameter affects mesh behavior

- Industrial applications

- How to choose the right mesh for your requirement

And how Alankrit Wire Craft manufactures custom mesh sizes for global industries.

What Is Mesh Size?

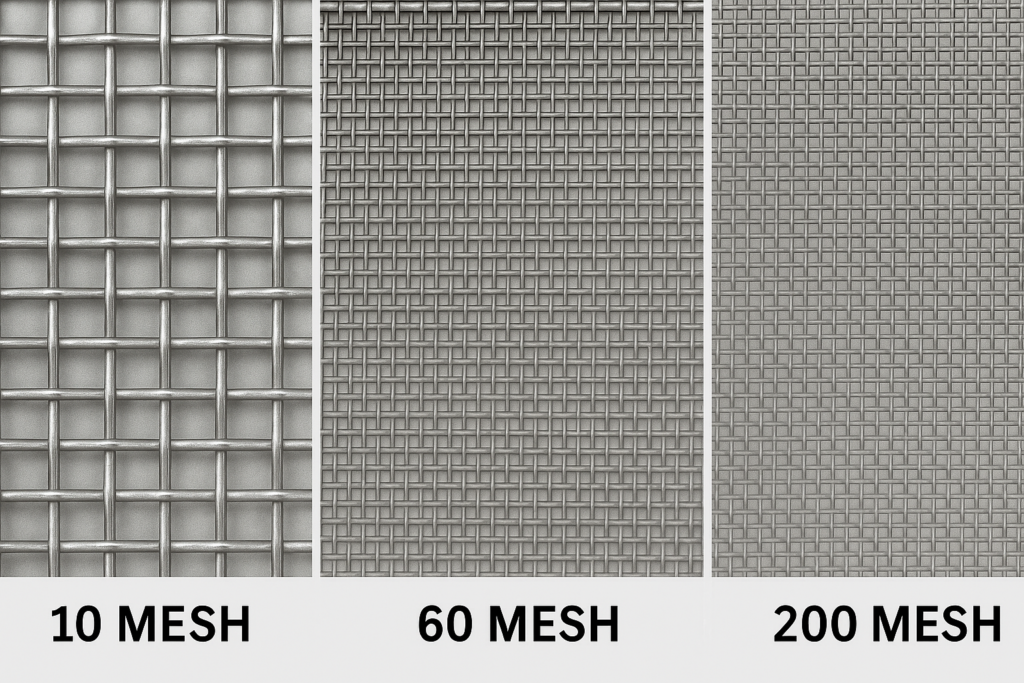

Mesh size refers to the number of openings in the mesh per linear inch.

Examples:

- 10 Mesh → 10 openings/inch → large openings → coarse

- 60 Mesh → 60 openings/inch → medium

- 200 Mesh → very small openings → ultra-fine

The higher the mesh count, the smaller the opening — and the more refined your filtration will be.

Impact of Mesh Size on Filtration

1. Flow Rate

Coarse mesh → faster flow

Fine mesh → controlled, slow flow

2. Filtration Precision

Coarse → removes large particles

Fine → removes fine powders and contaminants

3. Clogging Behavior

Ultra-fine mesh tends to clog faster, so requires proper flow management.

What Is Aperture?

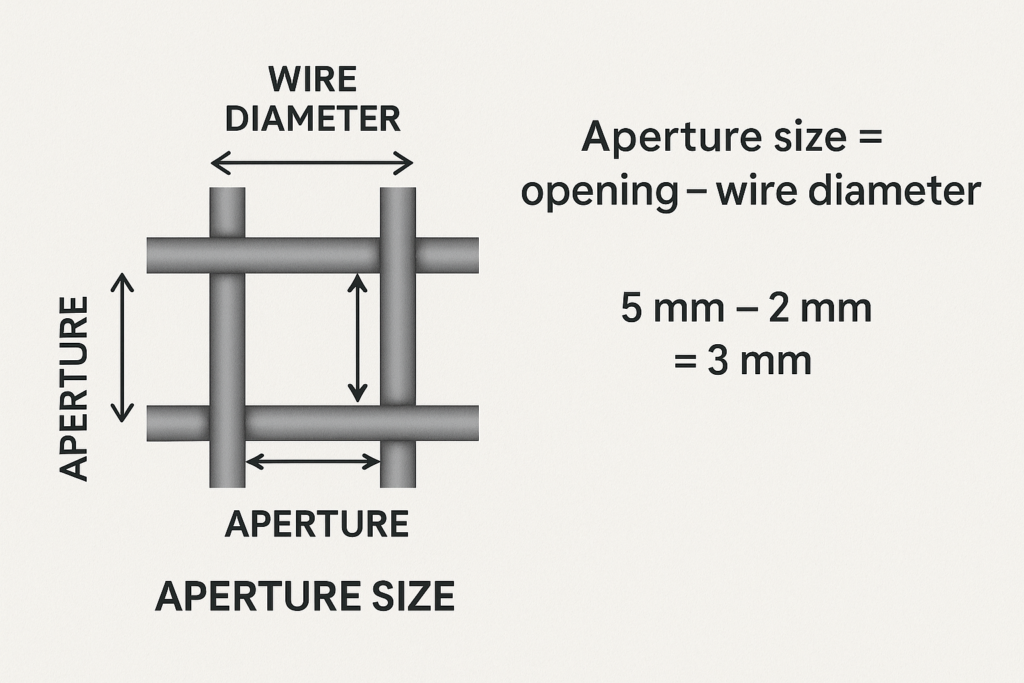

Aperture refers to the actual open space between wires.

Even two meshes with the same mesh count can have different apertures if the wire diameter varies.

Example:

- Fine wire → larger opening

- Thick wire → smaller opening

This changes flow rate, filtration accuracy, and strength.

Wire Diameter & Its Role in Filtration

The thickness of the wire affects:

- Mesh strength

- Lifespan

- Aperture

- Resistance to pressure

Thicker wires = stronger but slower flow

Thin wires = weaker but allow faster filtration

Mesh Size Requirements Across Industries

Food Industry

Applications:

- Flour sieving (80–120 mesh)

- Sugar & spice filtering

- Grain cleaning (10–20 mesh)

Mesh must be food-safe (SS 304) and easy to clean.

Pharmaceuticals

- Powder uniformity

- Fine powder screening (100–250 mesh)

- Contamination-free processing

Ultra-fine apertures needed.

Chemical & Petrochemical

- Liquid-gas filtration

- Catalyst handling

- Solvent filtration

Mesh must withstand high temperature + chemicals → SS 316 recommended.

Construction & Aggregates

- Sand screening (10–30 mesh)

- Cement quality testing (5–20 mesh)

- Aggregate separation

Requires durable, thick-wire mesh.

Water Treatment

- Pre-filtration

- Sediment removal

- Reverse osmosis pre-screens

Mesh size depends on sediment particle size.

How to Choose the Right Mesh Size?

1. Identify the particle size you want to filter

The smaller the particle, the higher the mesh count.

2. Understand your flow rate requirement

High flow → coarse mesh

Controlled flow → fine mesh

3. Identify the environment

Corrosive? High-temp? Use SS 316.

4. Decide strength requirements

Heavy load → thicker wire

Fine filtration → thin wire

5. Consult a specialist

Alankrit Wire Craft provides mesh recommendations tailored to your industry.

Conclusion

Mesh size and aperture directly impact filtration performance and final product quality. Selecting the correct mesh ensures better efficiency, reduced downtime, and long-term reliability.

Alankrit Wire Craft manufactures custom mesh sizes, apertures, wire diameters, and stainless steel grades for every industrial requirement.