Introduction

For industries dealing with high-pressure liquids, gases, chemicals, or viscous materials, single-layer mesh often fails to deliver consistent performance. That’s where multi-layer stainless steel wire mesh filters become essential. They combine strength, precision, and durability to handle critical industrial requirements.

Industries like petrochemicals, pharmaceuticals, water treatment, and food processing depend on these multi-layer structures for safety and efficiency.

What Are Multi-Layer Wire Mesh Filters?

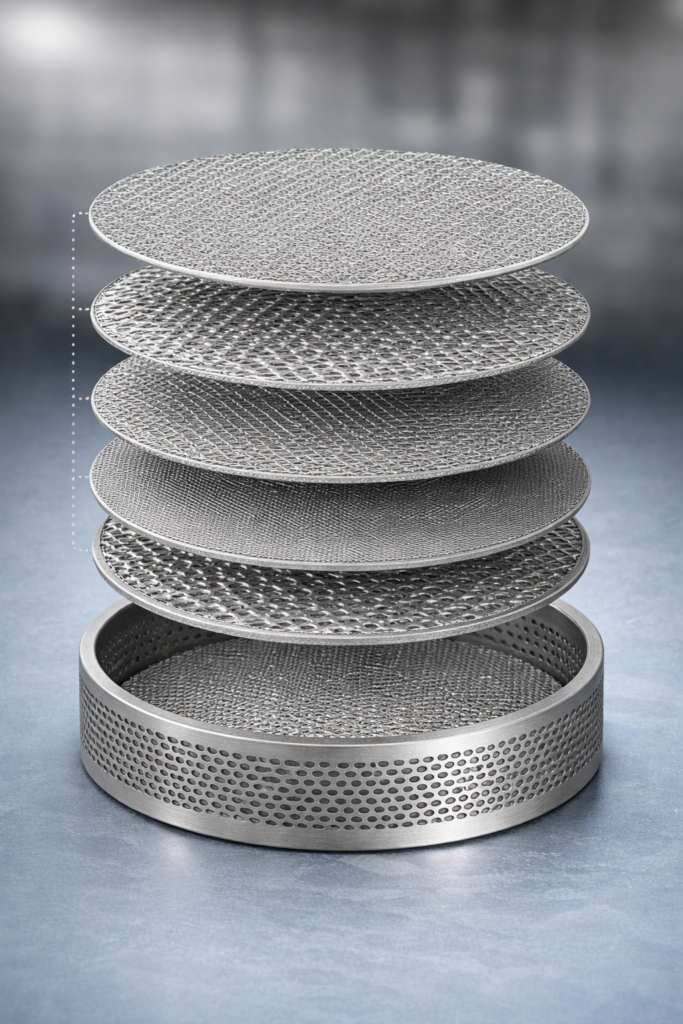

These filters are made by layering multiple screens of different mesh sizes and bonding them through:

- Sintering (heat bonding)

- Diffusion bonding

- Welding

Each layer has a specific purpose:

- Top layer → protection

- Middle layers → precision filtration

- Bottom layer → support

Advantages of Multi-Layer Filters

1. Superior Strength for High-Pressure Filtration

High-pressure pipelines and chemical reactors need filters that won’t deform.

Multi-layer mesh maintains shape even under intense pressure.

2. Consistent Filtration Accuracy

Different layers trap particles at different levels, ensuring uniform filtration.

3. Longer Service Life

Multi-layer filters resist:

- Wear

- Heat

- Corrosion

- Pressure fatigue

4. High Flow Rate with Support

Support layers prevent clogging and allow better flow compared to single-layer fine mesh.

5. Versatile Customization

Mesh sizes, layers, bonding method, thickness — all customizable.

Industries That Use Multi-Layer Mesh Filters

1. Petrochemical & Oil Industry

Filtration of:

- Viscous liquids

- Petroleum products

- High-temperature chemicals

2. Pharmaceuticals

- Sterile filtration

- Powder processing

- Air & gas purification

3. Water Treatment Plants

- Sediment removal

- Activated carbon systems

- Pre-filtration for RO systems

4. Food Processing

- Edible oil filtration

- Beverage purification

- Powder sieving

5. Aerospace & Automotive

High-pressure fuel and lubrication filtration.

Types of Multi-Layer Filters We Manufacture

1. 3-Layer Mesh Filters

Protective → Filtration → Support

2. 5-Layer Sintered Mesh

Enhanced precision + strength

3. Multi-Layer Mesh Circles

Custom-cut discs for filtration housings

4. Multi-Layer Cylindrical Filters

Used in pipelines and reactors

Conclusion

Multi-layer filters offer unmatched filtration performance for demanding industrial environments. If your system requires stability, high-pressure tolerance, and fine filtration, multi-layer stainless steel mesh is the best solution.

Alankrit Wire Craft provides custom multi-layer mesh screens, cartridges, discs, and cylinders tailored to your specifications.