Introduction

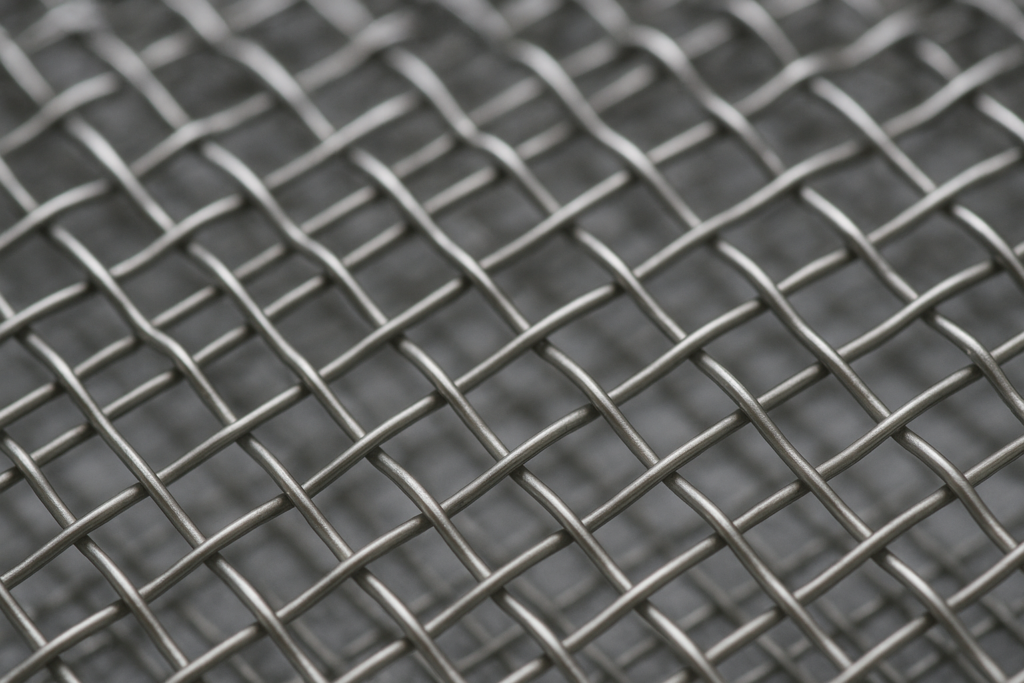

Filtration is at the heart of every industry – from producing life-saving medicines to ensuring the purity of drinking water. A reliable filtration system not only improves efficiency but also guarantees product quality. Among various filtration methods, stainless steel wire mesh stands out as one of the most trusted and versatile solutions.

In this blog, we’ll explore how industrial filtration works, why wire mesh is the preferred material, the different types of filters available, and how Alankrit Wire Craft delivers customized solutions for industries worldwide.

What is Industrial Filtration?

Industrial filtration is the process of separating solids from liquids or gases using a filtering medium. The goal is to remove impurities, protect machinery, and ensure product quality.

Industries that rely heavily on filtration include:

- Pharmaceuticals – removing contaminants from medicines

- Food & Beverages – ensuring hygiene and consistency

- Chemicals & Petrochemicals – handling corrosive substances

- Construction – testing raw materials like sand and cement

Why Stainless Steel Wire Mesh for Filtration?

Wire mesh filters, especially those made from stainless steel (SS 304 & SS 316), are widely used because of their unique advantages:

- High Durability – Resists wear and tear under pressure.

- Corrosion Resistance – Essential for industries dealing with chemicals and moisture.

- Temperature Tolerance – Performs reliably even under high heat.

- Reusable & Cost-Effective – Easy to clean and lasts longer than synthetic filters.

- Precision Filtration – Can be customized for ultra-fine or coarse filtration.

Types of Wire Mesh Filters Used in Industries

- Duplex Filters

- Provide continuous filtration with two filter chambers.

- Used in marine, oil & gas, and chemical industries.

- [Read our detailed blog on Duplex Filters →]

- Twill Wire Mesh Filters

- Known for strength and precision.

- Ideal for industries needing fine particle separation.

- [Learn more about Twill Wire Mesh →]

- Test Sieves

- Ensure material quality in construction, pharma, and food industries.

- [Discover applications of Test Sieves →]

- Wire Mesh Circles

- Cut-to-size mesh for specialized filtration equipment.

- [Benefits of Wire Mesh Circles →]

Applications Across Industries

- Pharma: Maintaining purity in drugs.

- Food Processing: Filtering grains, powders, and liquids.

- Construction: Ensuring material standards.

- Petrochemical: Handling high-pressure fluid systems.

- Automotive: Oil and fuel filtration.

How to Choose the Right Wire Mesh Filter

When selecting a filter, consider:

- Particle size requirement

- Operating conditions (pressure & temperature)

- Industry standards

- Custom sizing needs

💡 Pro Tip: Always consult an experienced manufacturer like Alankrit Wire Craft to get the right filter for your industry.

Why Choose Alankrit Wire Craft?

- Over 10 years of expertise in wire mesh manufacturing.

- Wide range of filters, sieves, and circles for multiple industries.

- Commitment to quality, precision, and customization.

- Serving both domestic and international markets.

📞 Contact us today for tailored industrial filtration solutions!

FAQs

Q1: How long does a stainless steel wire mesh filter last?

With proper maintenance, it can last several years.

Q2: Can filters be customized for specific industries?

Yes, Alankrit Wire Craft offers custom designs.

Q3: What’s the difference between plain weave and twill weave mesh?

Plain weave is simple and cost-effective; twill weave is stronger and suitable for fine filtration.

Conclusion

Industrial filtration is critical for maintaining product quality and efficiency across industries. Stainless steel wire mesh filters are durable, precise, and versatile – making them the go-to choice worldwide. With Alankrit Wire Craft’s expertise, you get high-quality filtration solutions designed for your industry’s unique needs.

👉 Explore our range of [Duplex Filters], [Twill Mesh], [Test Sieves], and [Wire Mesh Circles] today.