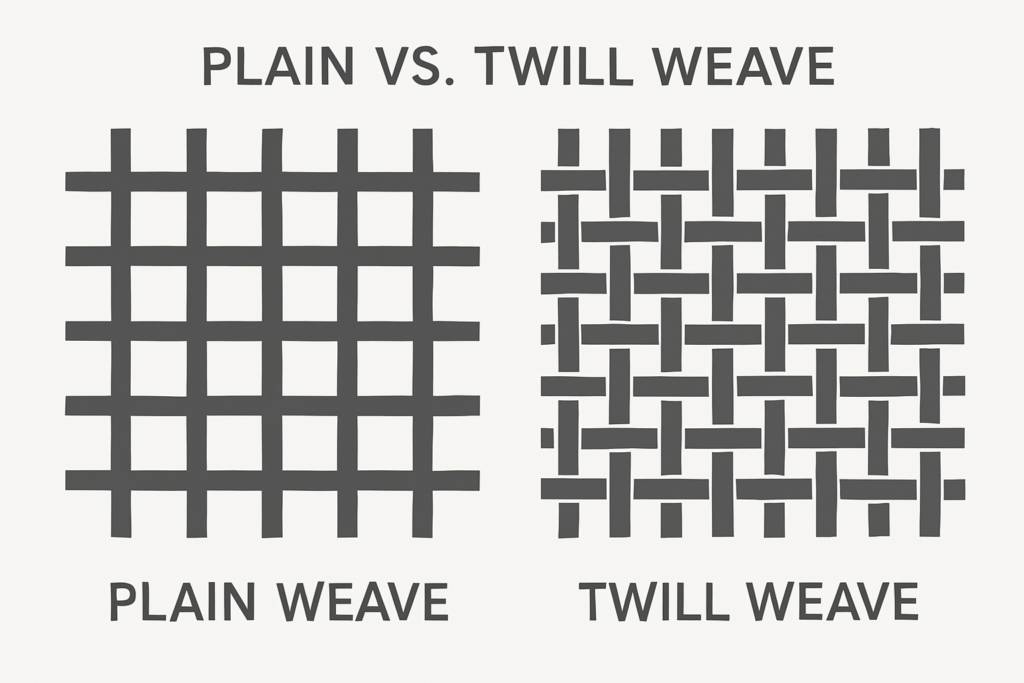

Choosing the correct wire mesh can make or break your operation. Let’s decode the two most popular options: Plain vs. Twill.

What Is Wire Mesh Weaving All About?

Wire mesh is made by weaving metal wires together — but how they are woven changes everything. The pattern impacts mesh strength, flexibility, filtration capability, and ideal use. At Alankrit Wire Craft, two types dominate customer demand: Plain Weave and Twill Weave.

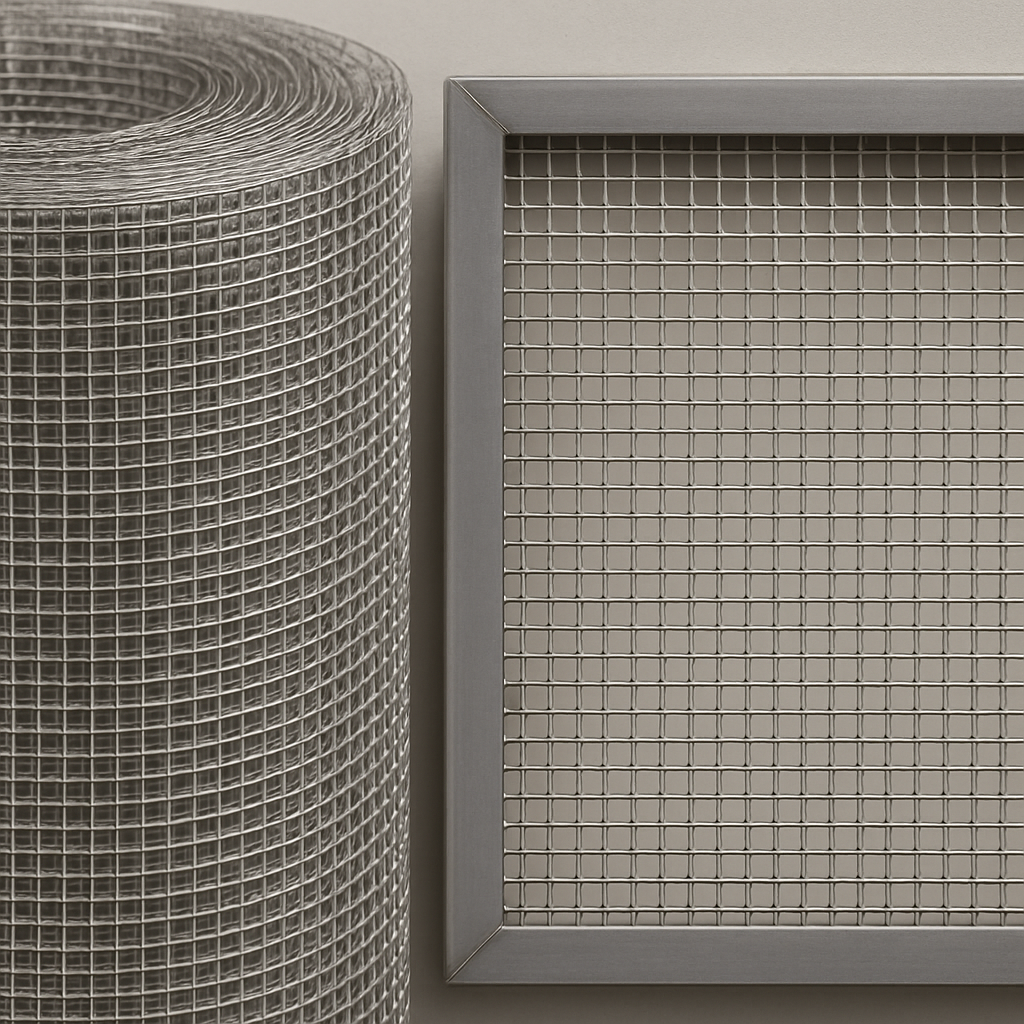

What is Plain Weave Wire Mesh?

Plain weave is the most basic and economical style. Each weft wire alternates over and under each warp wire, like a traditional textile.

Key Benefits:

- Simple, uniform structure

- High open area for airflow or light filtration

- Cost-effective

- Easy to clean and maintain

Best For:

- Air & water filters

- Window & machine guards

- Basic screening

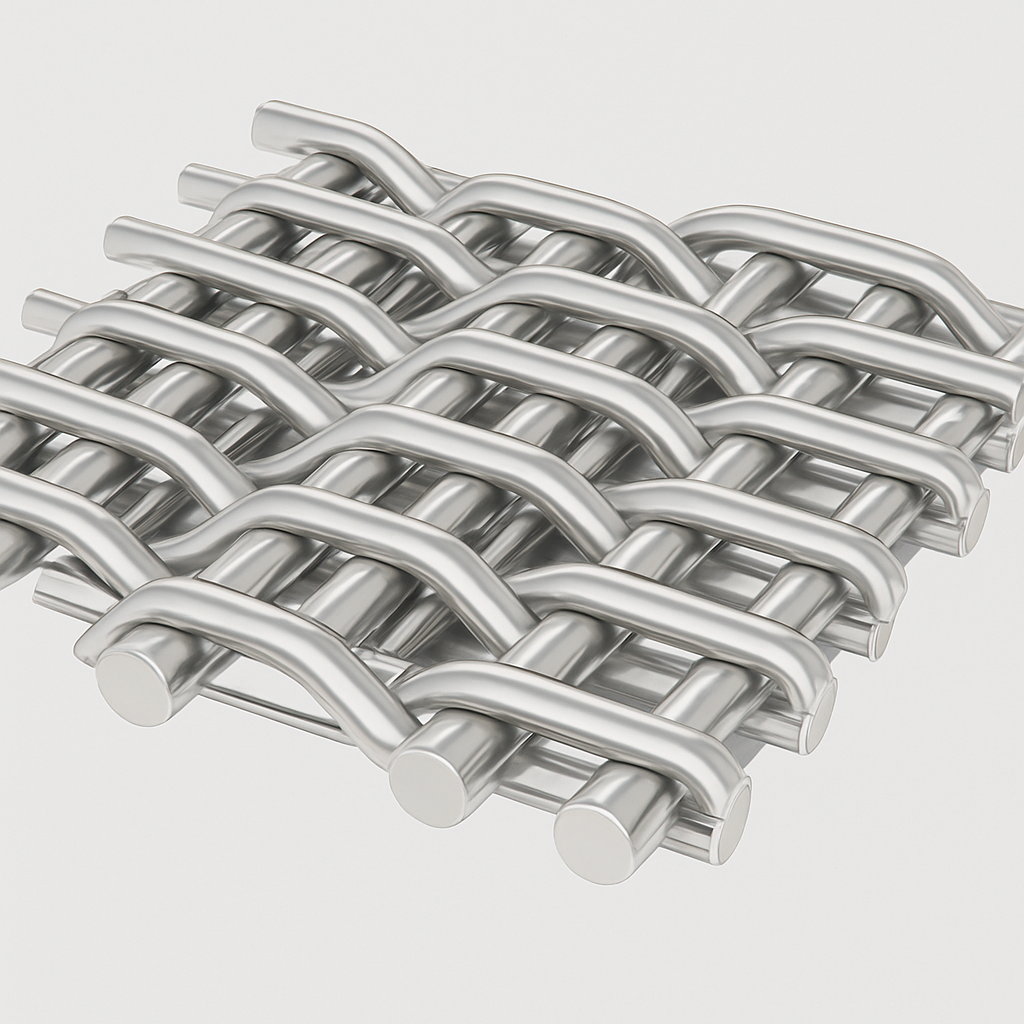

What is Twill Weave Wire Mesh?

In twill weave, wires pass over two and under two. This gives a tighter, more durable mesh with diagonal ribbing.

Key Benefits:

- Allows finer mesh count

- Higher strength than plain weave

- More resistant to high pressure and heat

Best For:

- Pharmaceutical & chemical filtration

- Powder sieving

- Fine particle separation

Plain Weave vs. Twill Weave: Quick Comparison

| Feature | Plain Weave | Twill Weave |

| Structure | 1 over, 1 under | 2 over, 2 under |

| Filtration | Standard | Fine to ultra-fine |

| Strength | Moderate | High |

| Flexibility | Low | Medium |

| Cost | Lower | Higher |

Expert Tip:

“Choose twill for high-pressure or fine filtering environments. Stick with plain weave when cost, airflow or light filtering are your priorities.” — Engineering Team, Alankrit Wire Craft.

Ready to Choose the Right Mesh?

Still unsure which one suits your operation? Let us help. 📧 Contact Us or 📞 Call Alankrit Wire Craft for expert guidance and fast delivery.