Introduction

Every industrial application—whether it’s filtration, separation, screening, safety, or processing—depends heavily on the material quality of the wire mesh being used. Stainless steel is the backbone of modern industrial mesh manufacturing because of its strength, corrosion resistance, heat tolerance, and hygienic properties.

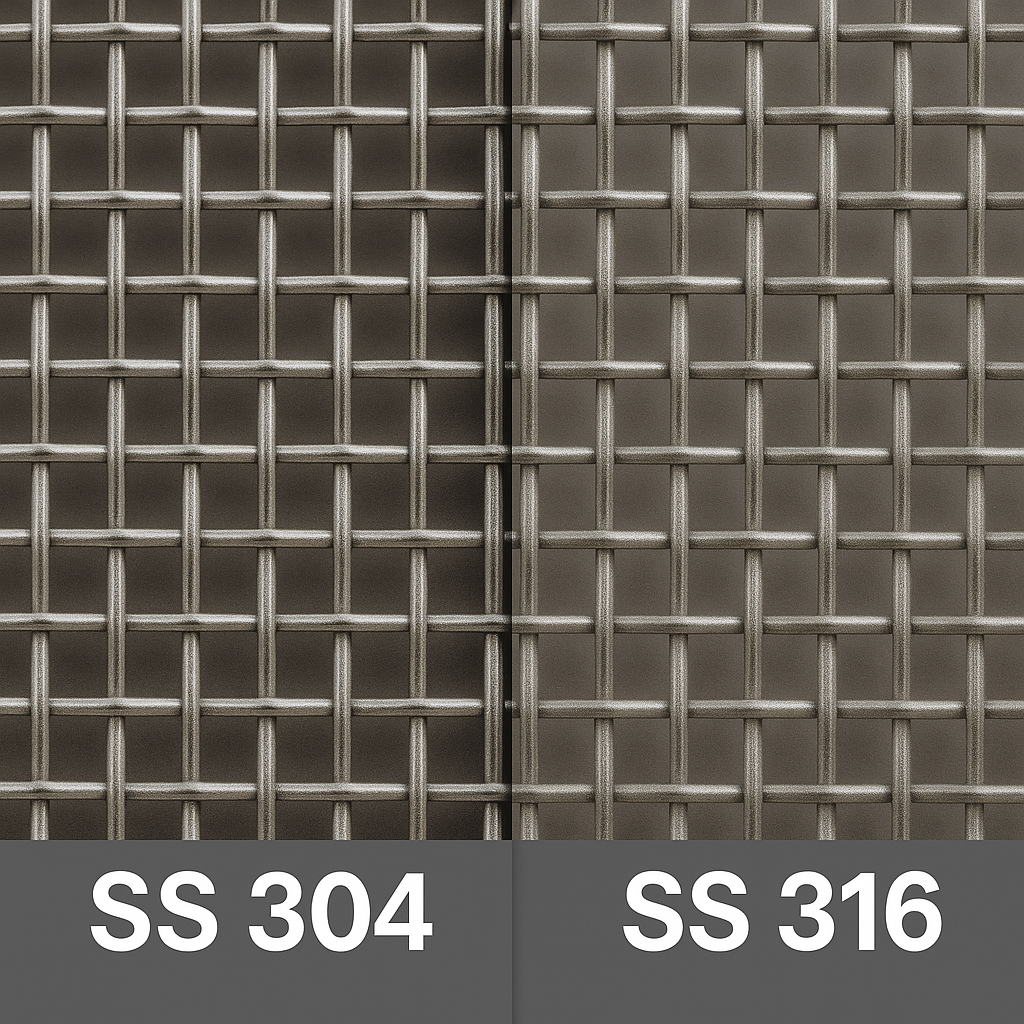

But not all stainless steel is the same. The two most widely used grades in industrial wire mesh manufacturing—SS 304 and SS 316—may look identical, but they behave very differently under harsh environments.

Choosing the right grade directly affects:

- Filtration efficiency

- Material lifespan

- Safety

- Corrosion performance

- Suitability for food, pharma & chemicals

- Cost-effectiveness

In this in-depth guide, we explore exactly how SS 304 and SS 316 differ, where each grade is used, and how choosing the right one impacts industrial operations.

Why Stainless Steel is the Preferred Material for Wire Mesh

Stainless steel offers unique advantages over mild steel, brass, aluminum or synthetic filters. Industries choose stainless steel for its durability, safety, and ability to withstand demanding conditions.

Major Benefits of Stainless Steel Wire Mesh:

1. Corrosion Resistance

Stainless steel contains chromium, which forms a protective oxide layer preventing rust—even in humid, chemical, or marine environments.

2. High Strength & Mechanical Stability

Unlike synthetic or plastic filters, stainless steel mesh retains strength under:

- Pressure

- Weight

- Structural stress

- High flow rates

3. Temperature Resistance

Stainless steel works well in extreme temperatures ranging from -200°C to 700°C, depending on the grade.

4. Hygienic & Easy to Clean

Perfect for food processing and pharmaceuticals where hygiene is mandatory.

5. Long Service Life

SS mesh can be cleaned, reused, and sterilized, reducing long-term costs.

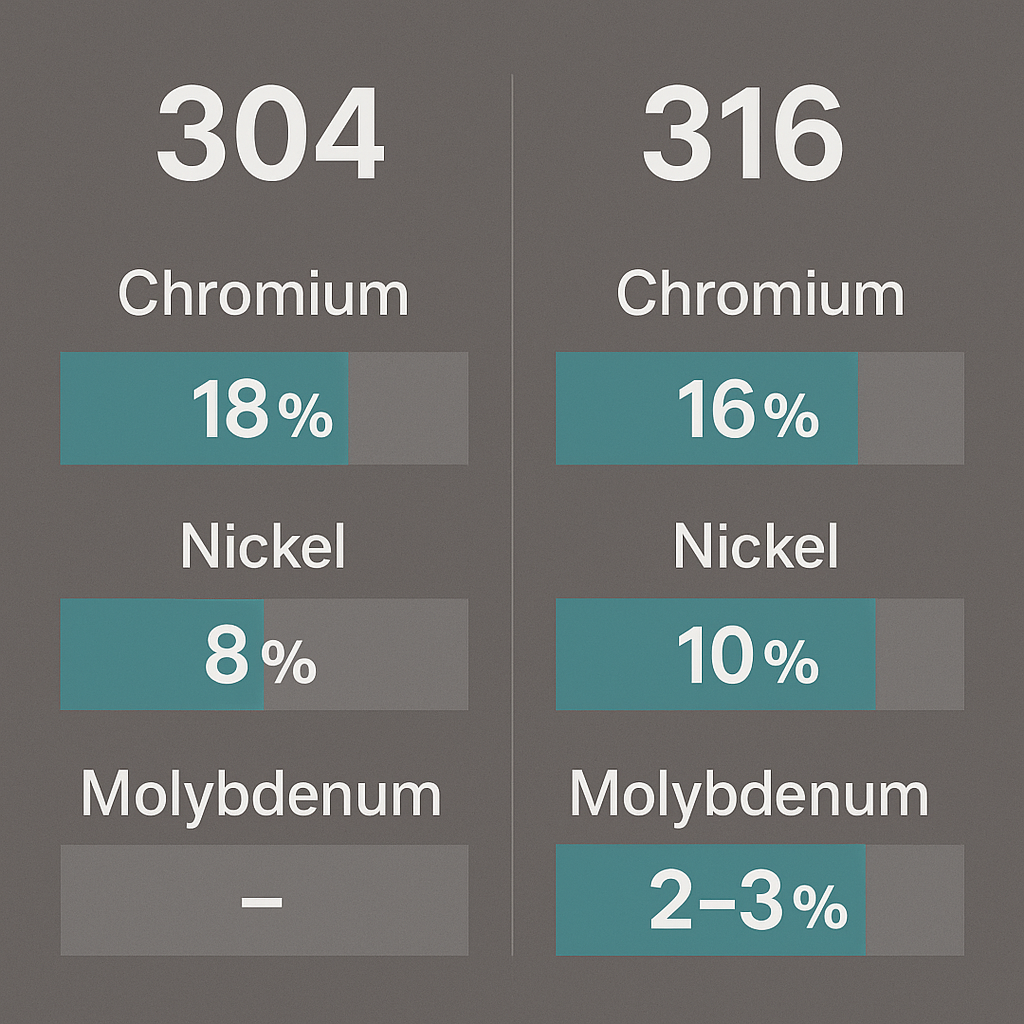

Understanding the Composition: SS 304 vs SS 316

Although both belong to the austenitic family, the chemical compositions differ enough to drastically change performance.

SS 304 Composition:

- Chromium: 18%

- Nickel: 8%

- Carbon: ≤ 0.08%

SS 304 is known as the “standard grade” for most industrial applications.

SS 316 Composition:

- Chromium: 16%

- Nickel: 10%

- Molybdenum: 2–3%

The presence of molybdenum (Mo) gives SS 316:

✔ Superior corrosion resistance

✔ Marine and chemical durability

✔ Better heat resistance

This is the reason SS 316 is often referred to as the “marine grade”.

Performance Differences Between SS 304 & SS 316 Wire Mesh

Finding the right grade depends on the environment and application.

1. Corrosion Resistance

SS 304:

- Resistant to mild corrosion

- Not suitable for chlorides or acids

SS 316:

- Highly resistant to chlorides, acids, and chemicals

- Withstands seawater, brine, chemicals, solvents

If your application involves harsh chemicals, moisture, or salt exposure — SS 316 wins.

2. Heat Resistance

SS 316 can withstand slightly higher temperatures due to molybdenum.

Ideal for:

- Steam filtration

- High-temperature chemical processing

- Petrochemical applications

3. Cost Differences

SS 316 is 15–25% costlier due to molybdenum content, but offers longer service life in harsh conditions.

4. Tensile Strength & Durability

Both grades offer strong tensile strength, but SS 316 performs better in corrosive environments over time.

5. Magnetic Properties

Both are non-magnetic in annealed form.

SS 304 can become slightly magnetic after cold working.

Which Grade Should You Choose?

Use SS 304 when:

✔ You need cost-efficient performance

✔ Environment contains no acids or chemicals

✔ Application includes general filtration, sieving, screening

Use SS 316 when:

✔ Exposure to acids, chemicals, seawater

✔ High-temperature systems

✔ High purity required (pharma, chemicals, food)

Industries That Depend on SS 304 and SS 316 Wire Mesh

1. Food & Beverage Industry

- Sieving flour, grains, sugar

- Filtration of liquids

- Hygiene-friendly & corrosion resistant

SS 304 is most commonly used, but SS 316 is preferred in salty or acidic foods.

2. Pharmaceuticals

- Powder sieving

- Sterile filtration equipment

- Tablet manufacturing

SS 316 is preferred due to its purity and corrosion resistance.

3. Chemical & Petrochemical

- High-temperature filtration

- Acidic/alkaline media

- Solvent filtration

SS 316 dominates due to chemical compatibility.

4. Marine & Offshore Applications

Saltwater corrosion demands SS 316 mesh.

5. Construction & Architecture

- Safety mesh

- Facades

- Reinforcement

- Ventilation screens

SS 304 is more common in building applications.

Why Choosing the Right Grade Saves Cost & Time

Choosing SS 316 when SS 304 is enough → unnecessary cost increase.

Using SS 304 in corrosive environments → early mesh failure.

Therefore, selecting the right grade ensures:

✔ Longer mesh lifespan

✔ Fewer replacements

✔ Better filtration quality

✔ Lower maintenance cost

✔ Safer operations

Conclusion

Understanding the differences between SS 304 and SS 316 is essential for making informed purchasing decisions. Whether you’re filtering chemicals, screening food ingredients, or protecting machinery, choosing the correct stainless steel grade can significantly impact your operations.

At Alankrit Wire Craft, we manufacture high-quality SS 304 and SS 316 wire mesh filters, sieves, circles, and custom mesh components for industries across the globe.